Tridex & Komet Inserts

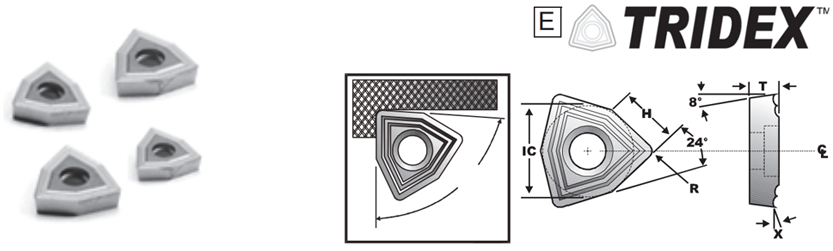

TRIDEX™ PREMIUM 84° TRIGON COATED INSERTS

A Major feature of the TRIGON insert is its 84° nose angle which combines the strength of a square with the versatility of a triangular insert. Prices are pulled from our database in real time. Press Add button to see product price.

| Coated Inserts | Uncoated Inserts | |||||||||

| Drill Dia | IC | T | H | X | R | Grade SZP40 Coated C2 | Grade SBP35 Coated C5 | - | Screw | Torx Driver |

| Steel, SS, Hi-Temp | Steel, SS | - | ||||||||

| 0.562 - 0.781 | 0.197 | 0.091 | 0.126 | 8° | 0.016 | TRX-197-SZP40-A |

TRX-197-SBP35-A |

- | SC-197-06-DK |

TX-206 |

| 0.812 - 0.937 | 0.250 | 0.125 | 0.161 | 8° | 0.016 | TRX-250-SZP40-A |

TRX-250-SBP35-A |

- | SC-250-06-DK |

TX-206 |

| 1.000 - 1.125 | 0.315 | 0.146 | 0.209 | 12° | 0.016 | TRX-315-SZP40-A |

TRX-315-SBP35-A |

- | SC-315-08-DK

|

TX-208 |

| 1.187 - 1.750 | 0.394 | 0.146 | 0.260 | 12° | 0.016 | TRX-394-SZP40-A |

TRX-394-SBP35-A |

- | SC-394-10-DK |

TX-210 |

| 1.812 -2.125 | 0.472 | 0.185 | 0.311 | 12° | 0.016 | TRX-472-SZP40-A |

TRX-472-SBP35-A |

- | SC-472-15-DK |

TX-215 |

| 2.250 - 2.500 | 0.591 | 0.205 | 0.390 | 12° | 0.016 | TRX-591-SZP40-A |

TRX-591-SBP35-A |

- | SC-472-15-DK |

TX-215 |

| 2.750 - 3.250 | 0.693 | 0.232 | 0.457 | 12° | 0.031 | TRX-693-SZP40-A |

TRX-693-SBP35-A |

- | SC-693-20-DK |

TX-220 |

SPEED & FEED INFORMATION

Made In Germany

| TRIDEX PREMIUM INSERTS | Brinell HardnessHB | Mach Group | DOC [in] Drill Dia. | SBP 35 | SZP 40 | ||||||||||

| f [in/.rev.] | f [in/rev/] | ||||||||||||||

| Mat. Group | Workpiece Material | .472 - .547 | .500 - .784 | .787 - 0.980 | .984 - 1.777 | >1.778 | .002 | .003 | .006 | .002 | .003 | .006 | |||

| P | Unalloyed steel | approx. 0.15% C annealed | 125 | 1 | .002 | .002 | .003 | .004 | .005 | 720 | 660 | 590 | 460 | 430 | 390 |

| approx. 0.45% C annealed | 190 | 2 | .002 | .002 | .003 | .004 | .005 | 720 | 660 | 590 | 460 | 430 | 390 | ||

| approx. 0.45% C tempered | 250 | 3 | .002 | .002 | .003 | .004 | .005 | 720 | 660 | 590 | 460 | 430 | 390 | ||

| approx. 0.75% C annealed | 270 | 4 | .002 | .002 | .003 | .004 | .005 | 720 | 660 | 590 | 460 | 430 | 390 | ||

| approx. 0.75% C tempered | 300 | 5 | .002 | .002 | .003 | .004 | .005 | 720 | 660 | 590 | 460 | 430 | 390 | ||

| Low-alloyed steep | annealed | 180 | 6 | .002 | .003 | .003 | .004 | .006 | 690 | 660 | 560 | 430 | 390 | 360 | |

| tempered | 275 | 7 | .002 | .003 | .003 | .004 | .006 | 690 | 660 | 560 | 430 | 390 | 360 | ||

| tempered | 300 | 8 | .002 | .003 | .003 | .004 | .006 | 690 | 660 | 560 | 430 | 390 | 360 | ||

| tempered | 350 | 9 | .002 | .003 | .003 | .004 | .006 | 690 | 660 | 560 | 430 | 390 | 360 | ||

| High-alloyed steel and high-alloyed tool steel | annealed | 200 | 10 | .002 | .002 | .002 | .003 | .004 | 620 | 560 | 490 | 430 | 390 | 360 | |

| hardened by tempering | 325 | 11 | .002 | .002 | .002 | .003 | .004 | 620 | 560 | 490 | 430 | 390 | 360 | ||

| Stainless steel | ferritic / martensitic, annealed | 200 | 12 | .002 | .002 | .003 | .004 | .005 | 520 | 460 | 390 | 430 | 390 | 360 | |

| martensitic, tempered | 240 | 13 | .002 | .002 | .003 | .004 | .005 | 520 | 460 | 390 | 430 | 390 | 360 | ||

| M | Stainless steel | austenitic2, retained | 180 | 14 | .002 | .002 | .003 | .004 | .005 | 660 | 590 | 520 | 520 | 490 | 460 |

| K | Grey cast iron | pearlitic/ferritic | 180 | 15 | .003 | .004 | .005 | .006 | .006 | 460 | 430 | 390 | 390 | 390 | 360 |

| pearlitic (martensitic) | 260 | 16 | .003 | .004 | .005 | .006 | .006 | 460 | 430 | 390 | 390 | 390 | 360 | ||

| Cast iron with spheroidal graphite | ferritic | 160 | 17 | .002 | .003 | .005 | .006 | .006 | 390 | 390 | 360 | 360 | 360 | 330 | |

| pearlitic | 250 | 18 | .002 | .003 | .005 | .006 | .006 | 390 | 390 | 360 | 360 | 360 | 330 | ||

| Malleable cast iron | ferritic | 130 | 19 | .003 | .004 | .004 | .005 | .006 | 460 | 430 | 390 | 390 | 390 | 360 | |

| pearlitic | 230 | 20 | .003 | .004 | .004 | .005 | .006 | 460 | 430 | 390 | 390 | 390 | 360 | ||

| N | Aluminum malleable alloys | non-age-hardenable | 60 | 21 | - | - | - | - | - | - | - | - | - | - | - |

| age-hardenable, age-hardened | 100 | 22 | - | - | - | - | - | - | - | - | - | - | - | ||

| Aluminum cast alloys | < 12% Si, non-age-hardenable | 75 | 23 | - | - | - | - | - | - | - | - | - | - | - | |

| < 12% Si, age-hardenable,-hardened | 90 | 24 | - | - | - | - | - | - | - | - | - | - | - | ||

| > 12% Si, non-age-hardenable | 130 | 25 | - | - | - | - | - | - | - | - | - | - | - | ||

| Copper and copper alloys (Bronze/brass) | Free cutting alloys, Pb > 1 % | 110 | 26 | - | - | - | - | - | - | - | - | - | - | - | |

| Brass, red brass | 90 | 27 | - | - | - | - | - | - | - | - | - | - | - | ||

| Bronze unleaded & electrolytic copper | 100 | 28 | - | - | - | - | - | - | - | - | - | - | - | ||

| Non-metallic materials | Duroplasts | - | 29 | - | - | - | - | - | - | - | - | - | - | - | |

| fiber-reinforced plastics | - | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Hard rubber | - | 30 | - | - | - | - | - | - | - | - | - | - | - | ||

| S | Heat-resistant alloys | Fe basis annealed | 200 | 31 | .002 | .002 | .002 | .002 | .003 | 260 | 230 | 230 | 200 | 200 | 200 |

| age-hardened | 280 | 32 | .002 | .002 | .002 | .002 | .003 | 260 | 230 | 230 | 200 | 200 | 200 | ||

| Ni or annealed | 250 | 33 | - | - | .002 | .002 | .003 | 160 | 130 | 130 | 130 | 130 | 130 | ||

| Co basis age-hardened | 350 | 34 | - | - | .002 | .002 | .003 | 160 | 130 | 130 | 130 | 130 | 130 | ||

| cast | 320 | 35 | - | - | .002 | .002 | .003 | 160 | 130 | 130 | 130 | 130 | 130 | ||

| Titanium alloys | Pure titanium | 4003 | 36 | - | - | - | - | - | - | - | - | - | - | - | |

| Alpha + Beta alloys,age-hardened | 10503 | 37 | - | - | - | - | - | - | - | - | - | - | - | ||

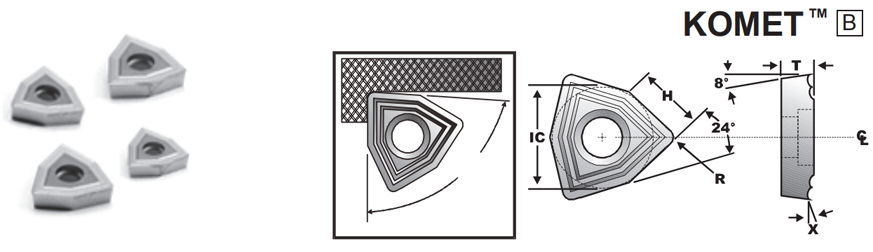

Genuine KOMET Inserts

Prices are pulled from our database in real time. Press Add button to see product price.

| Coated Inserts | Uncoated Inserts | |||||||||

| Drill Dia | IC | T | H | X | R | Komet Grade BK84 | Komet Grade K10 | Komet Grade P40 | Screw | Torx Driver |

| C5- Steels, Cast Steels, Stainless | C2- Aluminum Cast Iron | C5- Non-Alloy & Die Steels, SS | ||||||||

| 0.750 - 0.937 | 0.236 | 0.098 | 0.157 | 8° | 0.016 | KOM-0236-BK84 |

KOM-0236-K10

|

KOM-0236-P40 |

SC-236-06-DK |

TX-208 |

| 1.000 - 1.125 | 0.315 | 0.150 | 0.209 | 12° | 0.016 | KOM-0315-BK84 |

KOM-0315-K10 |

KOM-0315-P40 |

SC-315-08-DK |

TX-208 |

| 1.187 - 1.750 | 0.394 | 0.150 | 0.260 | 12° | 0.016 | KOM-0394-BK84 |

KOM-0394-K10

|

KOM-0394-P40

|

SC-394-10-DK |

TX-210

|

| 1.812 -2.125 | 0.472 | 0.189 | 0.311 | 12° | 0.016 | KOM-0472-BK84

|

KOM-0472-K10 |

KOM-0472-P40

|

SC-472-15-DK |

TX-215 |

| 2.250 - 2.500 | 0.591 | 0.209 | 0.390 | 12° | 0.016 | KOM-0590-BK84

|

KOM-0590-K10

|

KOM-0590-P40 |

SC-472-15-DK |

TX-215 |

| 2.750 - 3.250 | 0.693 | 0.236 | 0.457 | 12° | 0.031 | KOM-0693-BK84 |

KOM-0693-K10 |

KOM-0693-P40 |

SC-693-20-DK |

TX-220 |

GRADES AND SPEED/FEED INFORMATION

| Komet Grade | Application |

| BK84 | An TiCN/TiN-PVD coated grade which combines toughness with good wear resistance. For machining steel, cast steel and stainless steel. Because of the PVD coating, BK84 is the preferred grade for internal inserts for insert drills (less build-up on cutting edges). BK84 is also suitable for external inserts on insert |

| P 40 | Uncoated carbide with medium wear resistance at optimum toughness factor. Low to medium cutting speeds for roughing and with heavily interrupted cut. Also for unstable working conditions. For non-alloy steel, die steel and stainless steels |

| K 10 | Chamfered and neutral cutter geometry suitable for all grades of cast iron. Positively Molded (PD) and ground geometry is used for aluminum. E.g.:20 ° top rake, ground. Sharply and light honed. |

| BK 62 | TiCN and Al2O3-CVD-coating for higher cutting speeds in all types of cast iron materials. Only limited suitability for extreme interrupted cut. Not suitable for Aluminum materials. |

Helpful formula:

rpm = (3.82 X SFM) / (tool diameter)

| Material | Hardness (HB) | Speed (sfm) | Feed (ipr) | |||||

| Boring Depth 2x Dia / 3x Dia | Boring Depth 4x Dia | |||||||

| Drill Dia .750-.937 | Drill Dia 1.000-1.750 | Drill Dia >1.750 | Drill Dia .750 | Drill Dia .812-.937 | Drill Dia 1.000-1.750 | |||

| Mild steel | Up To 150 | 760-990 | .003-.005 | .003-.006 | .004-.006 | .001-.003 | .002-.004 | .002-.005 |

| Free cutting steel | Up To 150 | 660-930 | .003-.006 | .004-.007 | .005-.008 | .002-.004 | .002-.005 | .003-.006 |

| Mild case-hardened and heat-treated steel | 150-220 | 600-825 | .003-.005 | .003-.006 | .004-.006 | .002-.003 | .002-.004 | .002-.005 |

| Heat steel alloyed Cr and CrMo steel | 200-260 | 460-660 | .002-.005 | .003-.006 | .004-.006 | .002-.003 | .002-.004 | .003-.005 |

| Tool and heat-treated steels | <250 | 460-660 | .002-.004 | .002-.005 | .004-.006 | .001-.002 | .002-.003 | .002-.004 |

| 360-560 | 330-500 | .002-.003 | .002-.004 | .002-.005 | .001-.002 | .001-.002 | .002-.003 | |

| Stainless and heat-resistant steels Cr;CrNiu.CrNiMo-alloys | 150-270 | 400-600 | .002-.005 | .003-.006 | .004-.008 | .002-.003 | .002-.004 | .002-.005 |

| Hardened steels | Over 480 | 65-200 | .002-.003 | .002-.004 | .002-.004 | .001-.002 | .001-.002 | .002-.003 |

| Cast stee | Upto 200 | 500-825 | .002-.005 | .003-.006 | .004-.008 | .002-.003 | .002-.004 | .002-.005 |

| Cast iron | 180-250 | 330-660 | .004-.006 | .005-.008 | .006-.010 | .003-.005 | .003-.006 | .004-.006 |

| High strength cast iron/alloy cast iron | Over 250 | 330-500 | .003-.005 | .003-.006 | .004-.008 | .002-.003 | .002-.004 | .002-.006 |

| Aluminium alloys | Upto 80 | 825-1480 | .002-.004 | .002-.005 | .003-.006 | .001-.002 | .002-.003 | .002-.004 |

| 80-120 | 660-990 | .002-.005 | .003-.006 | .004-.006 | .002-.003 | .002-.004 | .002-.005 | |

| Over 120 | 500-825 | .003-.005 | .004-.006 | .005-.008 | .002-.003 | .002-.004 | .003-.006 | |

| Heat resistant super alloy (Cobalt based) | 65-260 | .001-.003 | .002-.004 | .002-.005 | .001-.002 | .001-.002 | .002-.003 | |

| Plastics solid | 500-990 | .004-.006 | .004-.006 | .005-.008 | .002-.005 | .003-.005 | .003-.006 | |