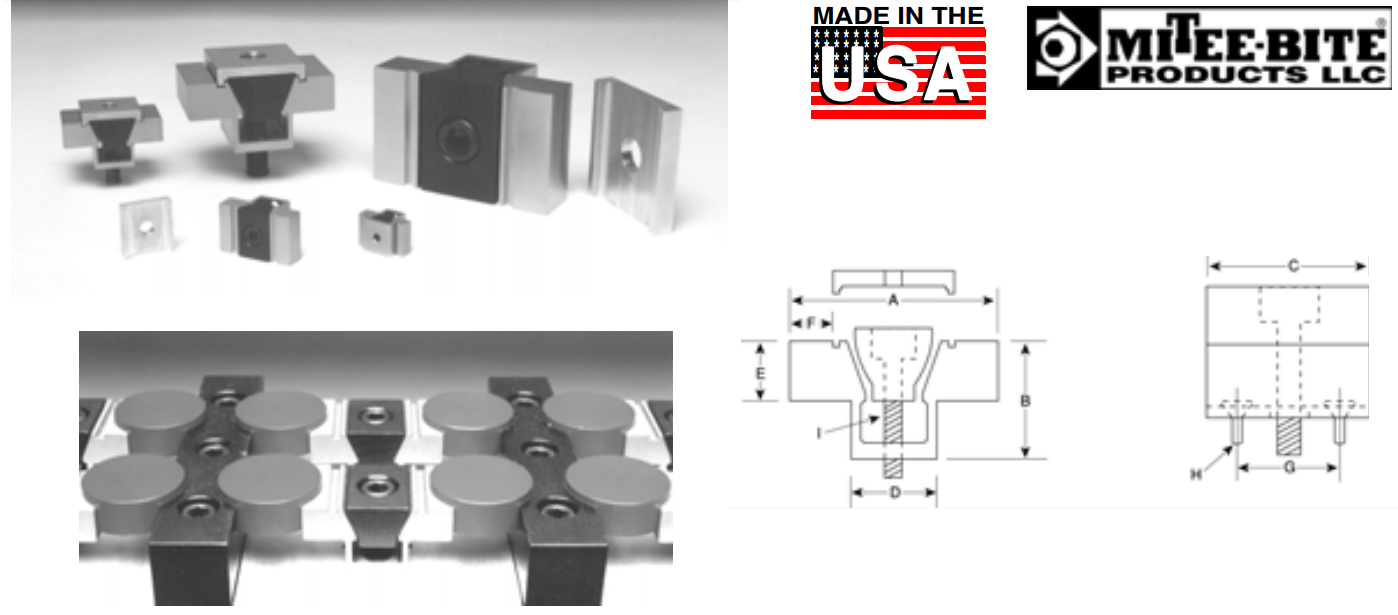

Machinable Uniforce Clamps

Now you can hold those round and unusual shape parts with ease. This compact method of workholding will allow more parts per load at a lower price than vise soft jaws. This compact Uniforce Clamp is available with extra material on the clamping jaws so it can be machined to conform to the shape of your workpiece. A unique locking plate is provided to make the clamp rigid while machining the jaws to your specifications, without vibration. Prices are pulled from our database in real time. Press Add button to see product price.

| Description | A* | B | C | D | E | F† | G | H** | I | Part Number |

| Clamp Assembly W/Plate | 1.125 | .50 | .62 | .420 | .25 | .18 | .400 | 2-56 | 8-32 | MITEE-60050 |

| Clamp Assembly, W/Out Plate | MITEE-60055 | |||||||||

| Clamp Assembly W/Plate | 1.50 | .75 | .94 | .632 | .37 | .26 | .625 | 6-32 | 1/4-20 | MITEE-60075 |

| Clamp Assembly, W/Out Plate | MITEE-60080 | |||||||||

| Clamp Assembly W/Plate | 2.00 | 1.0 | 1.25 | .820 | .50 | .39 | .812 | 6-32 | 5/16-18 | MITEE-60100 |

| Clamp Assembly, W/Out Plate | MITEE-60105 | |||||||||

| Clamp Assembly W/Plate | 3.00 | 1.5 | 1.87 | 1.215 | .75 | .62 | 1.20 | 10-32 | 1/2-13 | MITEE-60150 |

| Clamp Assembly, W/Out Plate | MITEE-60153 | |||||||||

| Clamp Assembly W/Plate | 4.00 | 2.0 | 2.5 | 1.625 | 1.0 | .80 | 1.625 | 1/4-20 | 5/8-11 | MITEE-60200 |

| Clamp Assembly, W/Out Plate | MITEE-60203 | |||||||||

| *A: The distance needed between workpieces for clamp clearance, drill and tap mounting holes on the center of “A” dimension. | ||||||||||

| †F: The amount of machinable stock on jaws. **H: Mounting Screws included. | ||||||||||